REFINING

MOL Group’s Refining product development team is fully committed to provide high level, professional and sustainable solutions for our internal partners to fulfil MOL Group's strategy. Based on the expertise of our well-trained, experienced product development and technical service engineers, scientists, and technicians we have developed several products which allow MOL Group to improve its performance and efficiency. These high-quality products provide for our customers better economics, increased performance and in case of fuels lower GHG emissions in line with the requirements and expectations of our customers and external stakeholders.

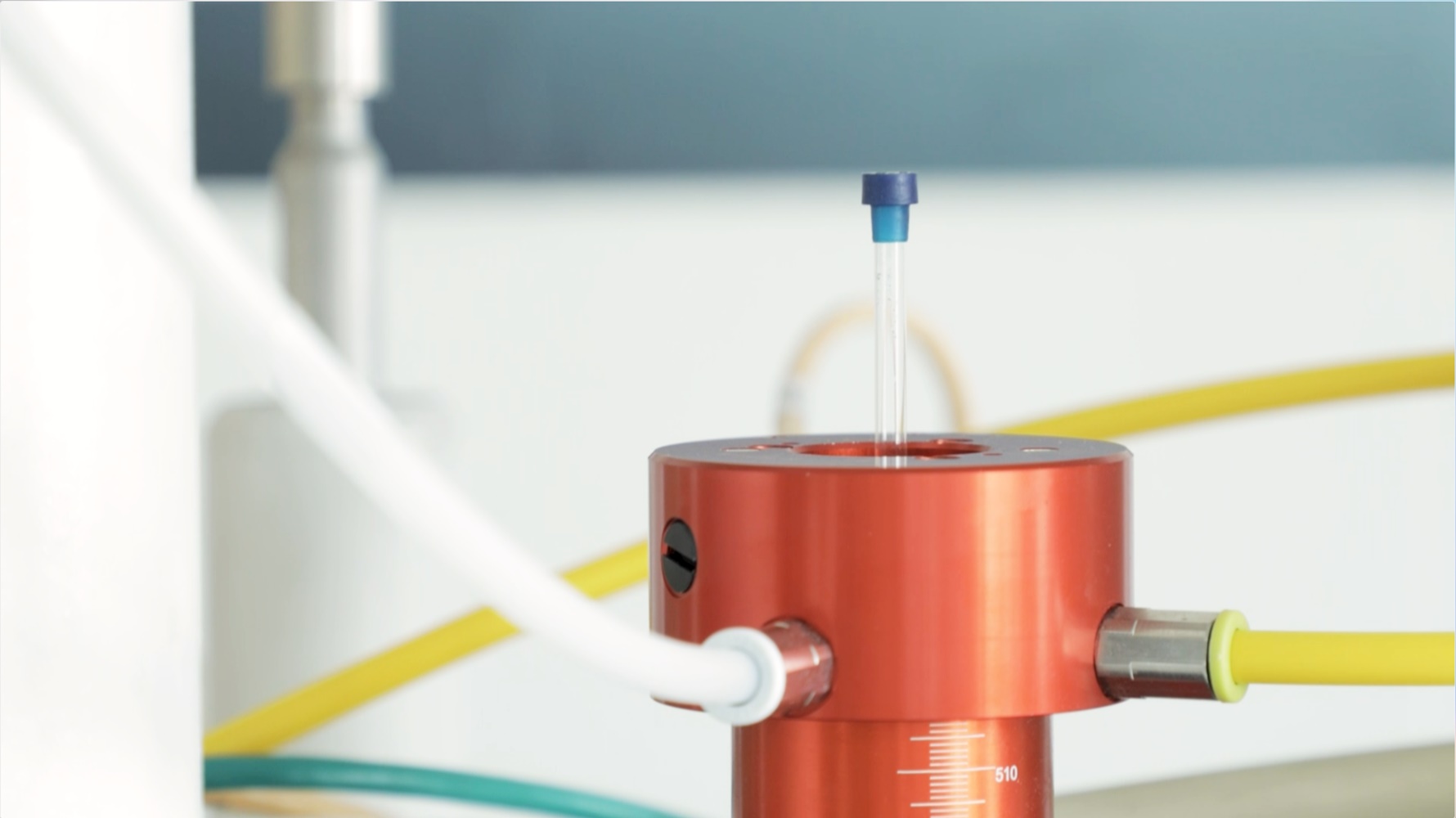

Our R&D laboratories have access to a specialty equipment portfolio. These assets enable us to provide small scale testing of non-catalytic and catalytic refining technologies as well as to test our products and additives with specialty analytical and non-routine application tests, including automotive tests. Thanks to these assets and knowledge, we are able provide technical solutions for the development of products and support troubleshooting tasks for our internal and external partners.

Our Main Activities

- Developing recipes for existing and new, innovative refining products – optimizing blending components, additive treatment, product evaluation

- Developing biofuels

- Developing research ideas and adaptation of new technologies

- Generating and developing of strategic R&D projects – e.g. co-processing of renewable feedstocks and utilisation possibilities of pyrolysis oil processed from non-bio origin

- Evaluating feedstocks, including crude oil evaluation

- Providing technical support to our partners – technological experiments, non-routine problem solving

Our Laboratories

MOL Group operates three laboratories in Hungary and Croatia. We collaborate closely with several other laboratories inside and outside of MOL Group.

Refining Development Laboratory

Our Refining Development Laboratory in Százhalombatta (Hungary) provides expertise for many activities throughout refining product development process. We are capable of developing and performing tailor-made analytical and application tests as well as to investigate and troubleshoot non-catalytic refinery technologies. With their unique expertise profile, our colleagues contribute strongly to the further development, optimization and troubleshooting of refinery processes and products.

Our laboratory capabilities include:

- Sample treatment/preparation/blending and additive treatment

- Elemental Analysis

- Chromatography

- Spectroscopy

- Bitumen testing

Catalytic and Automotive Technologies Laboratory

Our Catalytic and Automotive Technologies Laboratory in Százhalombatta (Hungary) operates a variety of small scale heterogenous reactors for different fix-bed catalytic refining technologies. Major catalytic processes, which can be tested in our reactor systems, include:

- Hydrocracking

- Heteroatom removals (HDS, HDN, HDO) and aromatic saturation

- Hydrogenation

- Isomerization

- Fluid Catalytic Cracking

Furthermore, a variety of automotive equipment is available to support the development of more efficient and cleaner fuels:

- Chassis dyno for drivability measurements on test vehicles

- Modern gasoline and diesel test cars

- Cold chamber for testing the cold-startability of passenger cars

- Non-engine specific water heating apparatus for testing the cold properties of diesel fuels

Central Testing Laboratory

Our Central Testing Laboratory (CTL) in Zagreb (Croatia) provides laboratory analysis services for crude oil and petroleum products, commercial fuels, biofuels, water, soil and waste to customers inside and outside of INA / MOL Group. With analytical equipment and professional staff, we are able to perform a variety of analyses quickly and reliably on a cost-competitive basis at CTL.

The laboratory offers sampling services for all types of products according to customer requirements. CTL also prepares professional expertise, research and development studies related to problem solving and offers other intellectual services.

CTL activities cover three pillars:

- Characterization of biomass, biofuels and renewable feedstocks: determination of structural carbohydrates, lignin, extractives, ash and moisture, raw materials for sustainable biofuel production, intermediate products analysis and soil analysis for cultivation of energy crops. The laboratory continuously develops new methods for biomass analysis.

- The preparation of Crude Oil Assays and characterization of oil is performed in the part of the laboratory specialized for such tests.

- Analysis and characterization of waste for permanent disposal, incineration and physical and chemical treatment, analysis of environmental parameters of wastewater and groundwater.

Since 2002, CTL is accredited according to the requirements of ISO/IEC 17025 standard (Accreditation Certificate No.1020) for liquid petroleum products and bio-fuels testing, sampling at gas stations as well as sampling for water, waste, sludge and soil and wastewater testing.

To learn more about CTL’s capabilities and services, please visit its homepage:

- Accreditation, authorisations and certified systems

- Service catalogue (PDF)

- Crude Oil Assays (PDF)

- Contacts