POLYOLEFIN

The world of polyolefin is undergoing significant changes. Geographical changes in supply and demand, increasing uncertainty in the regulatory environment, green aspirations driving MOL Group and the whole industry, and changing customer preferences and habits have brought unprecedented uncertainty to this business segment. We, at MOL Group Polyolefin Product Development, are working on to be a stable point in in the highly volatile, uncertain universe. We strive to maintain our profile of being a reliable and competent partner, with whom innovative, environmentally conscious, customer-oriented and lasting solutions can be created.

Recycling product development

In our continuously changing world, it is essential to provide sustainable technologies and products to our customers. Our engineers are experts in polymer development, waste processing technologies, chemical and mechanical recycling areas. We cooperate with scientific institutes and external industrial partners to create state of the art solutions in the field of recycled polymers.

Our polymer developments contain communal and industrial waste while featuring improved mechanical and rheological properties, and ensure compliance with the latest regulations.

We support MOL’s sustainability initiatives by investigating new opportunities and potential feedstocks in response to the latest economic and ecological challenges.

Chemical recycling, solvent based and advanced technologies

Our experts contribute to MOL Group 2030+ strategy by providing expertise to projects in the fields of chemical recycling, solvent based and other advanced technologies.

Since 2018, MOL Group and the German plastics recycling company APK AG collaborate strategically on plastics recycling. As a first step in this strategic cooperation, MOL Group supported the mechanical completion of APK’s 8 kt Newcycling® plant in Merseburg. The plant serves as a pilot for an innovative recycling process, Newcycling®, a solvent-based process that enables the selective separation of polymers in mixed plastic waste.

Mechanical recycling

Decades of experience in polyolefin development and a wide portfolio of own polymer products give us confidence in pursuing success in our mechanical recycling development projects. Many years spent on the analysis of waste feedstocks and recycled polymers provide the required background knowledge to find improvement potentials in the properties of our products, and to develop new products meeting the challenging demands of our customers.

Many years spent on the analysis of waste feedstocks and recycled polymers provide the required background knowledge to find improvement potentials in the properties of our products, and to develop new products meeting the challenging demands and sustainability targets of our customers.

Virgin and Compound Product Development

Product development teams in Hungary and Slovakia carry out research and development activities in the area of virgin polyolefins (LDPE, MDPE, HDPE, HomoPP, HecoPP, RacoPP) and PP compounding. We are committed to develop new innovative products and emerging technology solutions in cooperation with customers and external R&D partners for packaging, automotive, building & construction, medical and agriculture segments. The close connection to our end customers results in a comprehensive product portfolio that meets market requirements and helps our customers to achieve better performance.

Main product development directions and polyolefin applications include:

- PACKAGING – Rigid and flexible

- AUTOMOTIVE – Interior, exterior, underhood

- BUILDING & CONSTRUCTION

- CONSUMER GOODS - Extrusion, Blow moulding, Injection Moulding

- MEDICAL – Film, Blow Moulding, Injection Moulding

- AGRICULTURAL – Film, Fibre, Injection Moulding, Blow Moulding, Extrusion and Pipes

Our services:

- Production process optimization

- Technical problem solving, troubleshooting

- Enhancement of properties, efficiency improvement

- New product development for specific applications

Our Development Laboratory

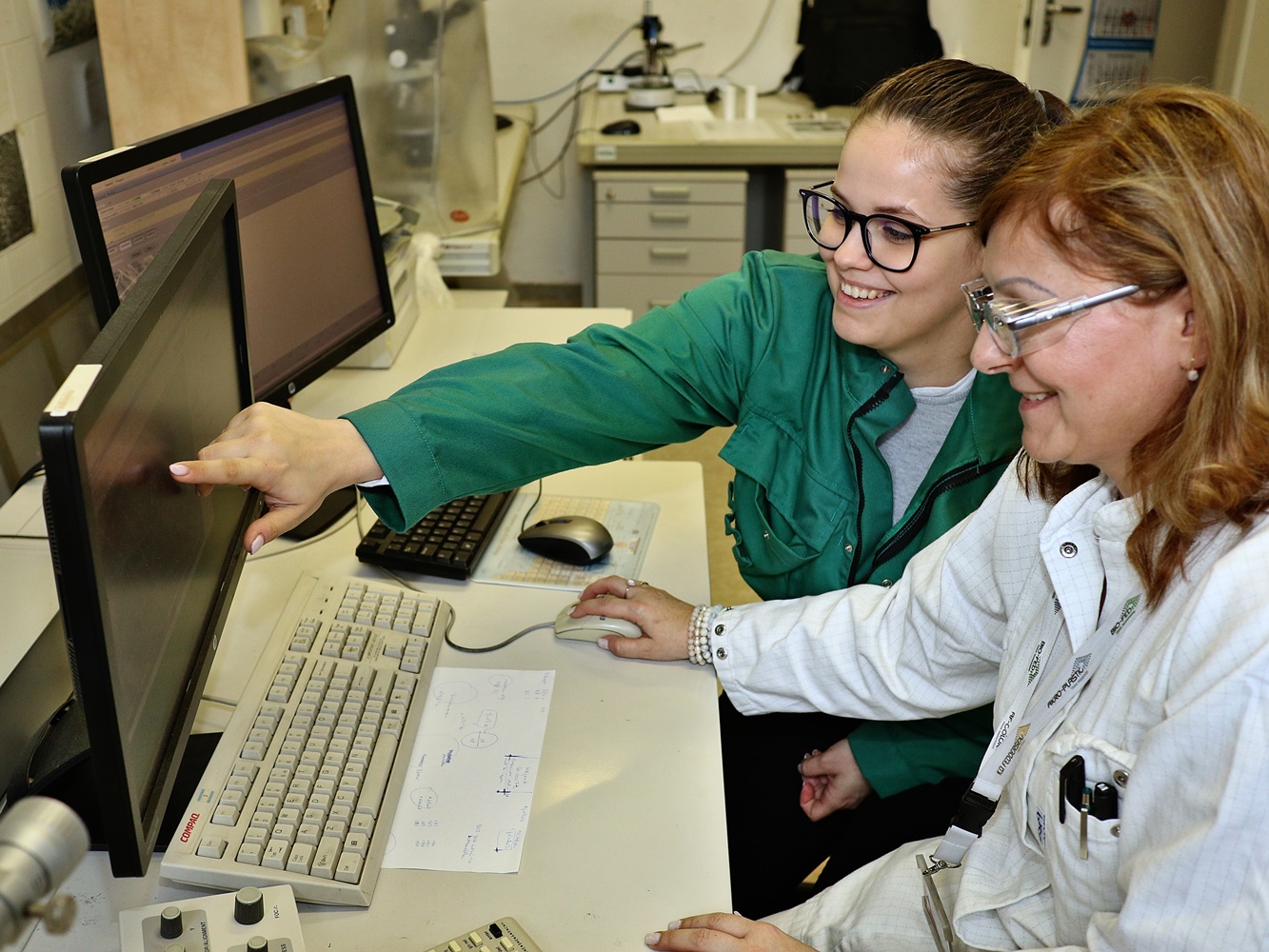

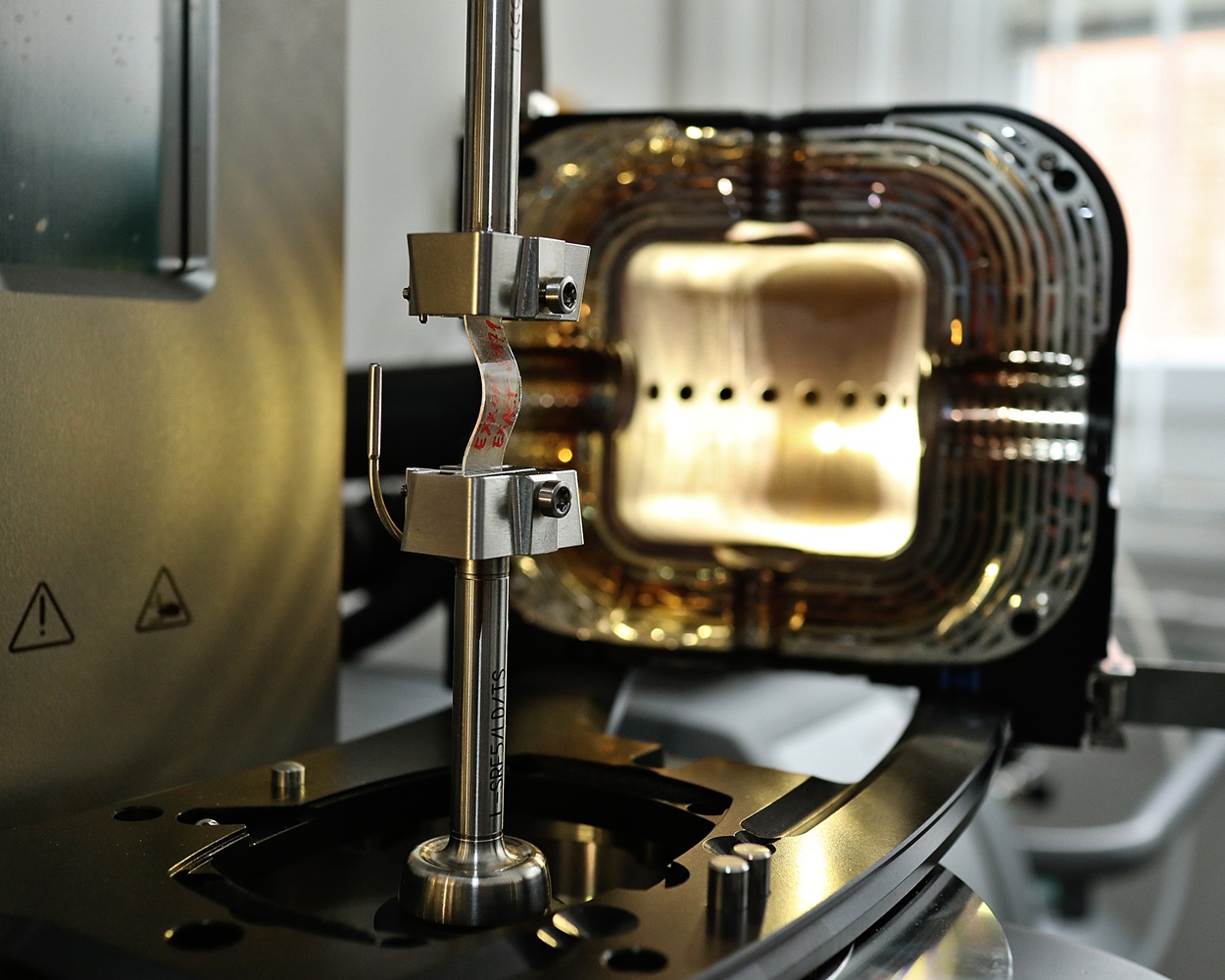

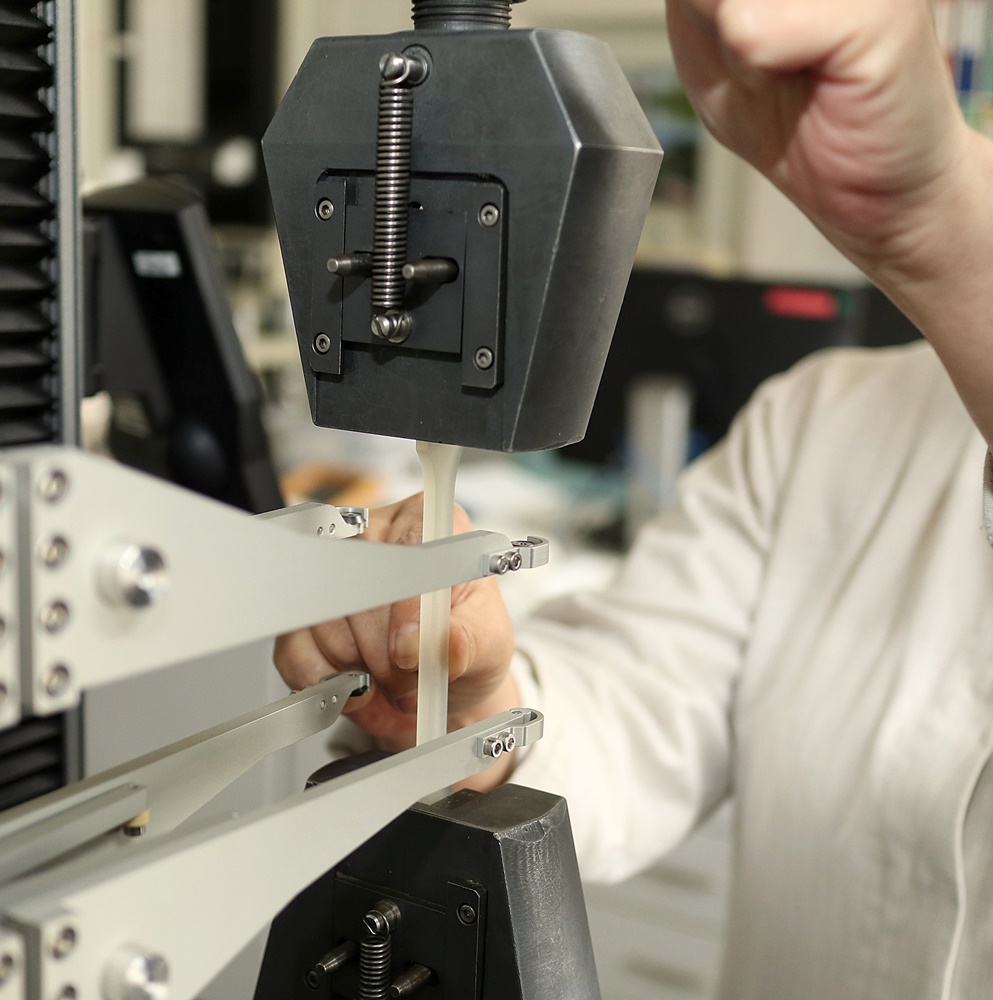

The Polyolefin Development Laboratory in Tiszaújváros (Hungary) can count on the expertise of several well-trained and experienced engineers and technicians. Our main fields of operation include polymer structure analysis, rheological measurements, mechanical and thermo-analytical tests. We are able to produce prototype polymer products on a laboratory scale on the basis of which experiments on larger scale can be initiated. For this, two well-equipped laboratory-size tank reactors and extruders (single screw and twin screw) are available.

Our modern and well-equipped laboratory is primarily used to support the product and application development of MOL Petrochemicals and Slovnaft, but we also provide our analytical expertise to improve our polyolefin production processes and to optimize the processing technology of our customers.

Would you like to learn more about successful product developments in MOL Group? Click here.

Our Polyolefin Product Development team will answer all your questions!